Oil Circuit Design of Hydraulic Pump Test-bed Based on Power Recovery

ABSTRACT: The research and development of hydraulic pump test-bed plays an important role in the production and testing of high-quality and high-performance hydraulic pumps. In this paper, the hydraulic circuit based on the power recovery hydraulic pump test-bed is designed, and the main oil circuit tests are carried out. The results show that the hydraulic oil circuit design meets the requirements.

Key words: hydraulic pump; structural design; simulation

Hydraulic pump life directly determines the reliability of the hydraulic system, which is widely used in the industrial field. At present, hydraulic system is widely used in domestic construction machinery and agricultural machinery to transfer power. At home and abroad, corresponding high-efficiency hydraulic pump test-bed is being developed. Hydraulic circuit is the key system of the test bed. It is very important to design an efficient hydraulic circuit.

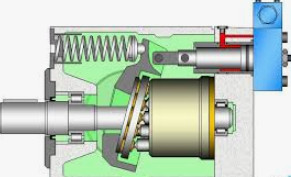

The durability test bench of hydraulic pump uses three-phase asynchronous motor to drive the tested hydraulic pump, and controls the speed and displacement of the tested hydraulic pump. In the test of hydraulic pump, adjusting the bi-directional output speed regulating motor 29 makes the speed of the tested hydraulic pump meet the set requirements. According to the corresponding test conditions, the opening and closing of hydraulic valves such as cut-off valve, throttle valve, solenoid switch valve and proportional solenoid relief valve are controlled to realize the corresponding test function. At the same time, the data of the torque meter, temperature meter, flow meter and other instruments in the hydraulic oil circuit are tested, and the durability of the tested pump is tested by computer analysis and processing.

Impact test. Impulse test is also a test method of durability test. Its oil circuit process is: intake tank refueling pump test pump 8 two three-way reversing valve 11 one-way valve 12 thermometer 13 pressure gauge 14 globe valve 17 globe valve 22 (throttle valve 23 / solenoid switch valve 24 throttle valve 25) return tank. 。 Among them, 23 is a small-diameter throttle valve and 25 is a large-diameter throttle valve. When the solenoid on-off valve closes, only the small-diameter throttle valve has hydraulic oil passing through. At this time, the system is in a high-pressure state.

When the solenoid on-off valve is opened, both throttle valves have hydraulic oil passing through, and the system is in a relatively low pressure state. In this way, by controlling the periodic opening and closing of the solenoid on-off valve, we can make the hydraulic system have a high and low pressure cycle impact, thus simulating the working environment of the hydraulic pump, and then testing the performance of the hydraulic pump.

The total efficiency of the hydraulic pump reflects the comprehensive performance of the hydraulic pump. After each durability test is completed, the efficiency test should be carried out, so that we can know what kind of state the pump performance is, whether the volume efficiency [5] and the total efficiency have decreased. The efficiency test of this scheme is mainly controlled by an electromagnetic proportional relief valve 21 to realize the change of pressure and flow in the hydraulic circuit, and then measure the performance parameters of the hydraulic pump.