Modular Hydraulic Piston Pump Automatic Device

Modular hydraulic piston pump automatic device is used to collect crude oil in directional vertical wells with diameter of 140, 146 and 168 m from 2 to 8_. Crude oil density is 0.87g/cm, water content is 90%, mechanical impurity is 0.1g/l, and hydrogen sulfide content is 0.01g/l at 120 C reservoir temperature.

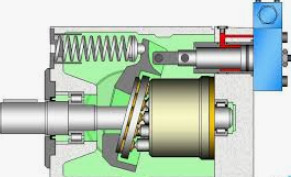

Hydraulic piston pump device is composed of oil well equipment and ground hydraulic station. Oil well equipment includes: wellhead equipment, clapper, hydraulic piston pump unit. The pump unit includes a free-moving hydraulic piston pump, which is suspended on the seat of the tubing string in the perforation area. The movable one-way valve hydraulic piston pump unit is a reciprocating piston pump with direct action and is driven by hydraulic pressure. The working fluid is dehydrated and impurity-free crude oil injected into the tubing under high pressure.

Under the action of working fluid, the piston of the engine transfers reciprocating motion to the piston of the pump. The piston of the engine passes through the upper and lower holes of the cylinder block, and traps the formation liquid into the annular channel between the tubing and the casing by the injected liquid flow. The hydraulic piston pump is lowered and placed on the base, and the pump is lifted up by the piston pump. The operation of salvaging the hydraulic piston pump is carried out in the salvage bin of the wellhead equipment.

The operation of putting and removing the piston pump is completed by two operators, without pressure relief, well killing and repair. The working fluid of the hydraulic piston pump is an open flow. When the working fluid is mixed with the oil, the mixed liquid passes through the wellhead equipment to the automatic metering room 6, and then goes to the surface hydraulic station including the process module 4 and the control module 5.

The inter-process module includes: 2.5 MPa three-phase separator and 2 branch sealed electric pumps with volume of 16 m', a set of hydraulic separator for removing mechanical impurities in working fluid, a charging unit with proportional quantitative pump, three plunger electric pump units working under 20 MPa pressure, and a working fluid distribution manifold with flow and pressure regulator and metering device.

Ground pressure stations have lighting, ventilation, heating and fire extinguishing systems. The electrical equipment in the process room is explosion-proof structure. All equipments of the ground hydraulic station are installed in two fully factory prefabricated, heat preservation and convenient transportation vehicle phase modules.

The main advantages of the hydraulic piston pump are that it can automatically replace the submersible pump in deep wells without minor repairs and kill the well within 1.5-2 hours; the use of the deep well pump can automatically save the supply of the pump without lifting the deep well pump to the ground by the inclination limit of the well; in the case of small storage, the waste heat of the process equipment can be used to realize the linkage of the submersible pump, thus improving the use efficiency; When surface pressure gauge or formation pressure is monitored directly, the repair interval of production wells can be equal to that of gas lift production without minor repair, and high active power can be obtained.